For house building, renovation and DIY it is worth buying from our company sawn timber, pine timber, and auxiliary materials for roof construction, which we provide ready to use with our various seriveces according to the needs of our customers.

Pine timber raw materials

Services

The Wood Plastic Composite (WPC) outdoor revetment is the blend of 60 percent bamboo fiber, 30 percent high-density polyethilene (HDPE) and 10 percent chemical additives, which are pressed at high temperature and pressure. Due to its high bamboo content, it combines the natural effects of wood with all the benefits of modern plastics.

Unlike lumber patio decking it does not require any extra surface treatment besides cleaning. (Especially in case of tropical speices accustomed to high humidity). For aesthetic reasons, however, the use of WPC patio oil should be considered, because it is expected to fade by 10 to 20 percent within 1 or 2 years as a result of UV radiation.

Structure:

Since their release parquet floors have been very popular with the customers They are not only easy to install but their surface can also be repolished 3-4 times so they can be used for decades. Their beautiful patterns are due to the grains of special wood species. The parquets we sell are made of wood species from all over the world. The reason why they should be chosen may also be our health, as dust mites causing allergies cannot colonize in them.

Maintenance: they can be vacuum cleaned and there are special cleaning, grooming and surface-repairing products recommended for parquets.

Underfloor heating: wood is a good insulator, therefore only parquets thinner than 14mm should be recommended for underfloor heating and wood species less prone to shrinking should be chosen. Manufacturers recommend a specific product for underfloor heating.

Benefits of parquets

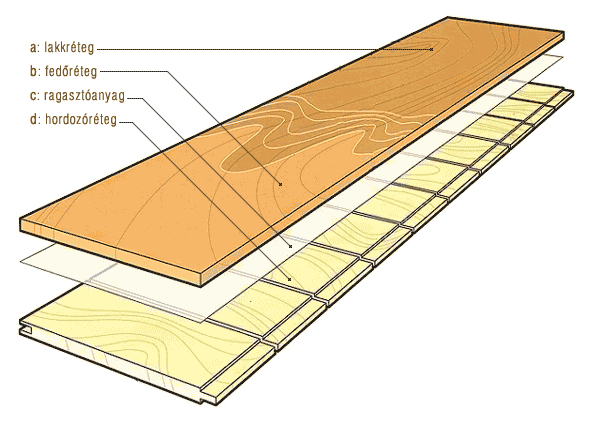

90 percent of the laminate flooring is made of wood with the help of a layering process. The top layer or wear layer is a synthetic resin coating over the decoration layer, under which the fiberboard core and finally the back layer at the bottom can be found. Its thickness is between 6-12mm, which makes it ideal for underfloor heating. The panels are fitted with high precision so that no gaps can arise between them. Their surface is extremly durable, not even cigarette butts or household solvents can damage it, the wear layer is pressure resistant.

Laminate floorpanels are usually available in a Drop Lock Click system to be installed without gluing Before buying it is advisable to consider the thickness and wear resistance of the laminate floor. Regular vacuuming is required for durability. Laminate floors must not be sanded as this may damage the abrasion resistant protective layer.

Important!

When calculating the quantity you should take into account that more than 10 percent more laminate flooring will be needed due to wastage. Also remember that you can only buy whole packages.

There are three ways to join laminate floor pieces together:

Laminate floor features

Barrier bags

Transport monitoring systems

Packaging aids

Plastic packaging tools

Pallets

Fillers, paddings